When it comes to choosing the right material for construction, fabrication, or industrial applications, stainless steel pipes are a popular choice due to their strength, corrosion resistance, and durability. However, one common point of confusion among buyers is choosing between stainless steel rectangular pipes and square pipes.

Both options are made from high-quality stainless steel and offer excellent performance, but their structural shapes, uses, and benefits differ. This blog explores the key differences between these two types of pipes, their applications, and when to use one over the other.

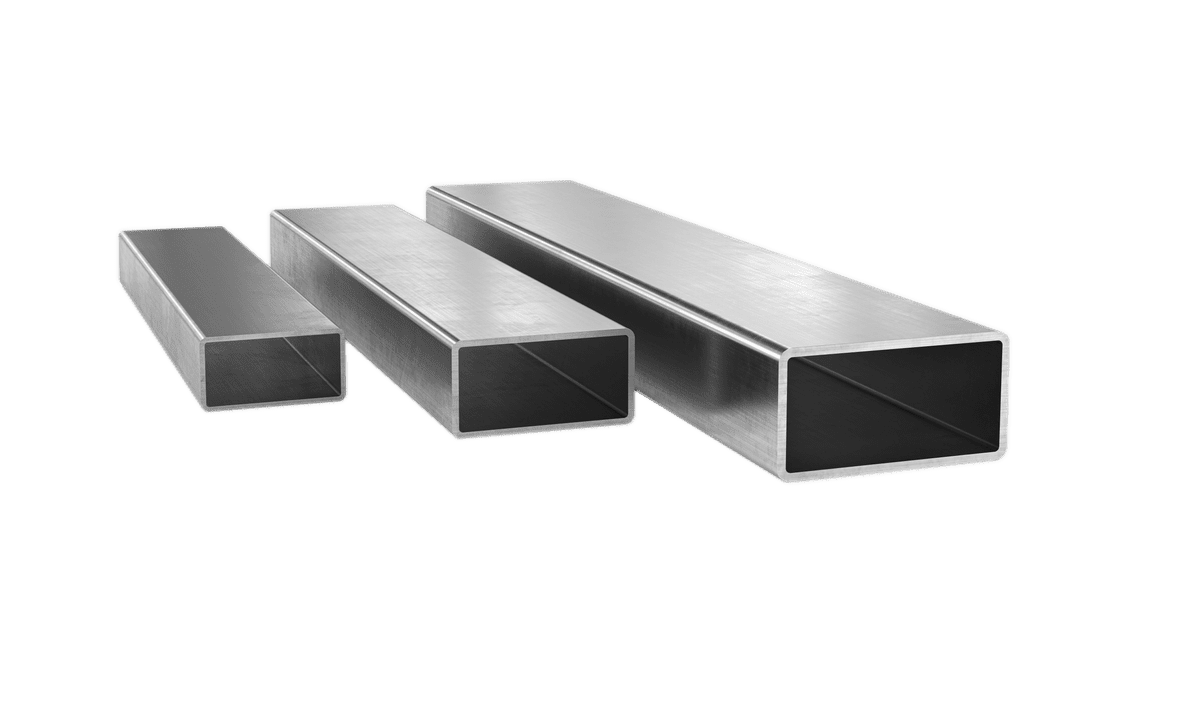

What Are Stainless Steel Rectangular Pipes?

Stainless steel rectangular pipes are long, hollow pipes that have a rectangular cross-section. These pipes are widely used in structural and architectural applications due to their excellent strength-to-weight ratio and clean, modern design. Their shape allows them to bear more load in one direction, making them suitable for construction frameworks, support beams, and frames.

Manufactured using advanced techniques like hot rolling, cold drawing, or extrusion, these pipes are available in various grades, including SS 304, SS 316, and SS 202, depending on the end-use requirements.

What Are Stainless Steel Square Pipes?

On the other hand, stainless steel square pipes have an equal width and height, forming a perfect square in cross-section. Their uniform geometry provides balanced strength across both axes, making them suitable for light structural work, fabrication, gates, fences, and general engineering purposes.

Like rectangular pipes, square pipes also come in various grades and finishes, making them ideal for both indoor and outdoor usage. Their sleek and symmetric shape often makes them a popular choice for visible or exposed installations.

Key Differences Between Rectangular and Square Pipes

Let’s compare stainless steel rectangular pipes with square pipes across various factors:

1. Shape and Design

- Rectangular Pipes: Elongated shape with differing width and height; suitable where directional strength is required.

- Square Pipes: Equal width and height; provides uniform load-bearing capacity in all directions.

2. Structural Strength

- Stainless steel rectangular pipes are stronger in the direction of the longer side, making them ideal for supporting horizontal or vertical loads.

- Square pipes provide balanced strength, which is beneficial for structures where equal support is needed on all sides.

3. Weight Distribution

- Due to their shape, rectangular pipes distribute weight unevenly — they are stronger along the longer edge.

- Square pipes provide even distribution of stress, which can be useful for some structural applications.

4. Aesthetics

- Stainless steel rectangular pipes offer a sleek and contemporary appearance, which is widely used in architectural applications like railings, window frames, and furniture.

- Square pipes offer a bold, uniform look often used in fencing, gates, and decorative elements.

5. Applications

- Rectangular pipes: Construction frames, trusses, bridges, support beams, columns, architectural elements.

- Square pipes: Fencing, gates, furniture frames, handrails, frames for machines and equipment.

Common Applications of Stainless Steel Rectangular Pipes

The unique design of stainless steel rectangular pipes makes them versatile for many sectors. Let’s look at where they are commonly used:

1. Construction and Infrastructure

Used for columns, beams, and supporting frameworks in buildings, bridges, and industrial sheds. Their ability to bear directional loads makes them ideal in high-stress areas.

2. Architectural Design

These pipes are favored in modern architectural designs due to their sleek profile. They are used in railings, doors, curtain walls, and window frames for both commercial and residential buildings.

3. Automotive and Transportation

Stainless steel rectangular pipes are used in chassis construction, trailer frames, and structural parts of vehicles due to their strength, lightweight nature, and corrosion resistance.

4. Furniture Manufacturing

The stylish rectangular shape and shiny finish make them ideal for modern furniture, tables, chairs, and display units. Their strength ensures long-lasting use, even in heavy-duty environments.

5. Industrial Equipment

Used in equipment framing, conveyor systems, machine guards, and platforms where stability and strength are crucial.

Common Applications of Stainless Steel Square Pipes

While similar in function, square pipes serve a different set of needs:

1. General Fabrication

Their balanced shape makes square pipes suitable for fabrication shops creating metal structures, machine bases, or support frames.

2. Fencing and Gates

Square pipes are commonly used in perimeter fencing, gates, and grills for residential, commercial, and industrial properties.

3. Railings and Handrails

In staircases and balconies, square pipes offer safety and symmetry, which is visually appealing and structurally reliable.

4. Interior Decor

Used in decorative partitions, display units, or modular interiors where geometric design is appreciated.

5. Light Structural Support

Ideal for small sheds, stands, and lightweight structural installations.

Grades and Finishes Available

Both stainless steel rectangular pipes and square pipes come in different grades based on the application:

- Grade 304: Most commonly used grade for general purposes. Good corrosion resistance.

- Grade 316: Offers higher corrosion resistance; suitable for marine and chemical environments.

- Grade 202: A budget-friendly option for low-corrosion applications.

Finishes include:

- Mill Finish – Raw, unfinished surface.

- Brushed Finish – Smooth, satin finish for aesthetics.

- Mirror Finish – High-gloss, reflective surface used in decorative applications.

Advantages of Stainless Steel Rectangular Pipes

- Excellent Strength-to-Weight Ratio: Ideal for heavy-duty structural support.

- High Corrosion Resistance: Performs well in outdoor, marine, or chemical environments.

- Low Maintenance: Easy to clean, durable, and long-lasting.

- Versatility: Available in various thicknesses, lengths, and finishes.

- Eco-Friendly: Stainless steel is 100% recyclable.

How to Choose the Right Pipe for Your Application

Consider the following before choosing between stainless steel rectangular pipes and square pipes:

- Load Requirements: Rectangular pipes are better for directional load-bearing; square for even distribution.

- Design Needs: Choose rectangular for sleek aesthetics, square for symmetric designs.

- Budget: Rectangular pipes may cost slightly more due to customization and finishing.

- End Use: For structural projects, rectangular is often preferred; for fencing or decor, square pipes are suitable.

Conclusion

Both stainless steel rectangular pipes and square pipes have their own advantages, and the choice depends entirely on the project requirements. Rectangular pipes offer better strength along one axis and are used where structural performance is critical. On the other hand, square pipes provide uniform support and are ideal for general applications.

Whether you’re building a skyscraper or designing a stylish railing, choosing the right type of stainless steel pipe is essential for the success of your project.

Looking for Stainless Steel Rectangular Pipes?

If you are in the market for stainless steel rectangular pipes, we are a trusted India-based supplier with a strong presence in the global market, including the USA. We offer a wide range of stainless steel pipes in different shapes, sizes, grades, and finishes all manufactured to international standards.

Our pipes are widely used in construction, architecture, automotive, and general fabrication across the USA. With competitive pricing, timely delivery, and consistent quality, we are your go-to source for stainless steel piping solutions.