Every successful construction project relies on a strong foundation, not just in terms of engineering, but also in the quality of the equipment and systems used. In Jalandhar, a city known for its industrial strength, scaffolding accessories manufacturers and formwork system manufacturers are setting new standards in durability, safety, and precision. From raw steel to a finished structure, these players are critical in ensuring projects stand the test of time while meeting strict safety guidelines.

The Critical Role of Scaffolding in Construction

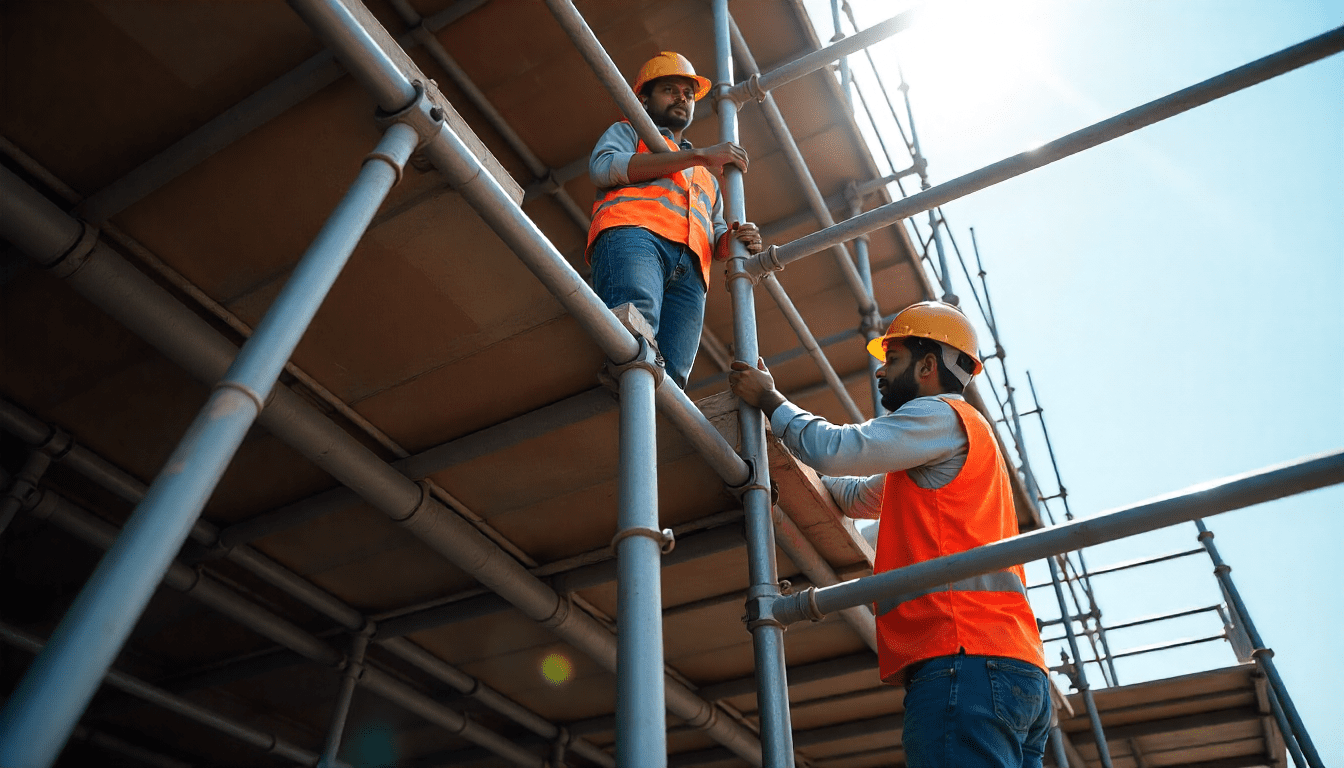

Scaffolding is not just temporary support — it’s the lifeline for workers, tools, and materials during construction, maintenance, and repair. The quality of scaffolding accessories manufacturers in Jalandhar influences the stability and safety of these structures.

Whether it’s couplers, base plates, ledgers, or braces, each accessory has to meet high standards. Reliable manufacturers in Jalandhar invest in high-grade steel, precision machining, and rigorous testing to ensure their scaffolding components can withstand heavy loads and harsh site conditions.

Why Jalandhar Has Become a Manufacturing Hub

Jalandhar’s industrial growth is rooted in its skilled workforce, advanced machinery, and decades of manufacturing expertise. The city’s scaffolding accessories wholesalers in India supply both domestic and international markets, known for delivering consistency in quality.

Local manufacturers have adopted automation and CNC machining to enhance precision, while also ensuring affordability, making Jalandhar a desirable sourcing destination for builders across India and abroad.

The Rise of Formwork Systems

While scaffolding supports workers externally, formwork systems create the moulds that give concrete its final shape internally. The introduction of advanced systems, such as the aluminium formwork system in Jalandhar, has transformed the speed and quality of modern construction.

Aluminium formwork is lightweight yet strong, making it easier to transport and assemble. Its reusability across multiple projects reduces long-term costs for contractors. Unlike traditional timber formwork, aluminium systems provide smoother finishes, reducing the need for excessive plastering and post-construction corrections.

For high-rise buildings, mass housing schemes, and infrastructure projects, aluminium formwork has become a preferred choice — and Jalandhar’s manufacturers are at the forefront of this shift.

Integration Between Scaffolding and Formwork

In large-scale construction, scaffolding and formwork systems must work together seamlessly. For instance, formwork requires access points for pouring and finishing concrete, which is made possible by the surrounding scaffolding. This coordination demands that scaffolding accessories manufacturers in Jalandhar and formwork system manufacturers collaborate closely to ensure compatibility, safety, and efficiency.

Why Builders Prefer to Buy Scaffolding Formwork Accessories Locally

When contractors choose to buy scaffolding formwork accessories from local manufacturers in Jalandhar, they benefit from:

- Faster turnaround times due to reduced shipping delays.

- Customisation options to meet unique project specifications.

- After-sales support for maintenance and replacement needs.

- Competitive pricing without compromising on quality.

These advantages have made local sourcing an industry trend for large projects where delays can lead to significant financial losses.

Innovation in Scaffolding Accessories

The best scaffolding accessories manufacturers in Jalandhar aren’t standing still. They are incorporating:

- Hot-dip galvanisation to improve corrosion resistance.

- Quick-lock systems to speed up assembly.

- Lightweight yet high-strength alloys to reduce manual handling risks.

These advancements not only improve safety but also boost productivity, which is a critical factor for modern construction firms.

Choosing the Best Formwork System in India

Not all formwork is created equal. Contractors searching for the best formwork system in India look for:

- Material quality — aluminium formwork systems are valued for longevity and precision.

- Ease of assembly — fewer parts and faster installation save time and labour costs.

- Reusability — a formwork system that can be reused multiple times maximises ROI.

- Compatibility — systems that integrate easily with scaffolding setups are preferred.

Manufacturers in Jalandhar are focusing on these priorities, ensuring their products remain competitive against global alternatives.

Sustainability in Manufacturing

Sustainability is no longer optional — it’s an industry expectation. Leading scaffolding accessories manufacturers in Jalandhar and formwork producers are implementing:

- Use of recyclable metals like aluminium and steel.

- Energy-efficient production to cut emissions.

- Waste reduction through precision cutting and reuse of scrap materials.

These measures not only reduce environmental impact but also appeal to developers committed to green building practices.

Sustainability in Manufacturing

Today’s buyers are also considering the environmental footprint of construction equipment. Both scaffolding accessories manufacturers in Jalandhar and formwork system producers are adopting:

- Recyclable materials like aluminium and steel.

- Energy-efficient manufacturing processes to reduce emissions.

- Waste-minimisation techniques in fabrication and finishing.

This focus on sustainability is not just about compliance — it’s a value-add that appeals to environmentally conscious developers.

People also read >> https://instantguestpost.blog/

Key Factors for Contractors to Consider

When selecting suppliers for scaffolding and formwork, contractors should review:

- Experience and portfolio — Proven track record in similar projects.

- Compliance with safety standards — Certifications and adherence to codes.

- Production capacity — Ability to handle large orders without delays.

- After-sales support — Availability of maintenance, repairs, and replacement parts.

Choosing the right supplier can mean the difference between a smooth project and costly setbacks.

Evolution of Scaffolding Accessories in Jalandhar

Over the past few decades, scaffolding accessories manufacturers in Jalandhar have moved far beyond producing only basic steel pipes and couplers. The city’s industry has embraced lighter yet stronger alloys, modular fittings, and easy-locking systems that save construction time. Early scaffolding was heavy, labor-intensive, and often lacked precision in design. Today, thanks to advanced machinery and improved metal treatment processes, accessories are more durable, corrosion-resistant, and compliant with global safety norms such as EN 74 and BS 1139. This shift not only meets the needs of local builders but also enables manufacturers to export to high-standard markets.

Final Thoughts

From the first steel cut to the final concrete pour, scaffolding accessories manufacturers in Jalandhar and formwork system manufacturers play a pivotal role in every phase of construction. Their expertise, innovation, and commitment to quality make them indispensable partners for builders seeking durability, safety, and efficiency.

Whether you’re looking to buy scaffolding formwork accessories, source from scaffolding accessories wholesalers in India, or invest in the best formwork system in India, Jalandhar offers solutions that meet global standards while staying cost-effective. The city’s blend of manufacturing excellence and modern engineering ensures that, from steel to structure, every project is built on a foundation of trust and performance.

For any query, visit https://www.vulco.in